The Guide To Electromagnetic Compatibility (EMC) Testing Methods

Make sure your products are functioning to the best of their ability and meet EMC compliance standards with our helpful guide to EMC testing methods.

What Is Electromagnetic Compatibility (EMC) Testing?

Electromagnetic Compatibility (EMC) testing measures the extent to which any electronic device, equipment, or system is functioning in an electromagnetic environment without being interfered with or introducing any electromagnetic interference to anything else.

Why Is Testing Electromagnetic Compatibility so Important?

EMC testing is essential in ensuring that devices in electromagnetic environments work. Furthermore, EMC compliance certifications are mandatory in the majority of markets around the world, including the US, Europe, China, Australia, and New Zealand. EMC compliance testing enables you to meet regulatory requirements as well as to improve the performance of your products.

EMC Categories

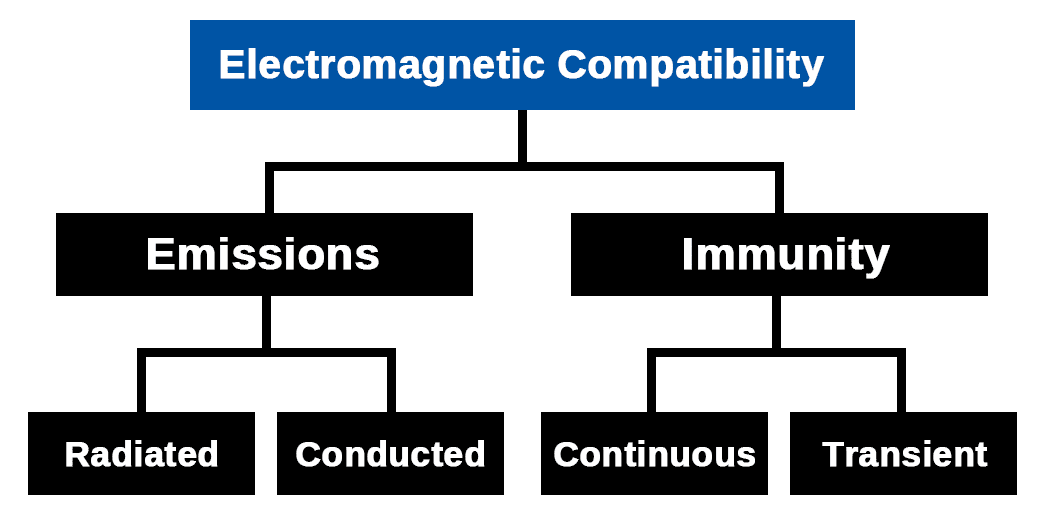

EMC is generally broken down into two different categories. These relate to the electromagnetic disturbances emitted by a device, and the susceptibility of a device to electromagnetic interference.

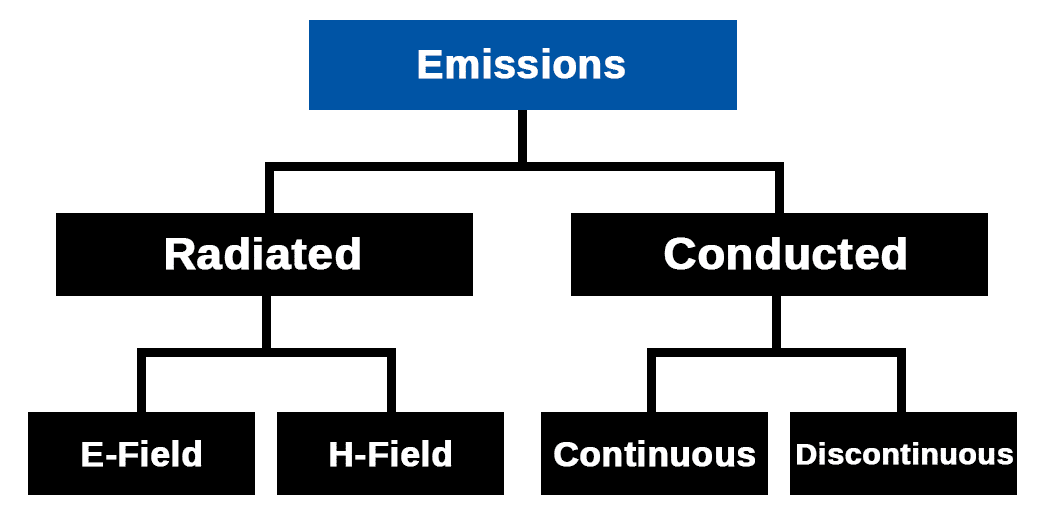

- Emissions: Emissions are the electromagnetic disturbances that emanate from an electronic system or device that may affect the performance/interfere with other electronic devices that are in the same environment. This stage of testing is typically known as Electromagnetic Interference or EMI.

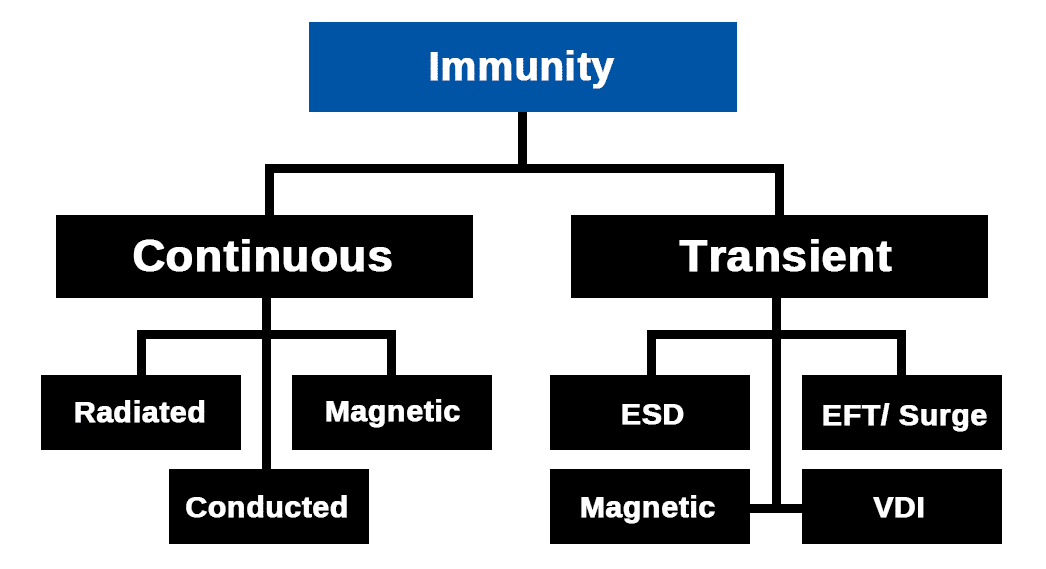

- Immunity and Susceptibility: This refers to the level to which an electronic device can adequately function in an electromagnetic environment without its functionality being affected by emissions from other electronic devices. Immunity is how resistant a device is, while susceptibility is how likely it is to be interfered with. The two terms serve as opposites.

We will now take a look at each of these categories in greater detail, explaining the different subcategories within them and EMC testing methods used.

Emissions Testing for EMC

There are two primary components within electromagnetic fields: the magnetic field (H-field), measured in amps per meter, and the electric field (E-Field), which is measured in volts per meter. This test is broken down into two parts, looking at two categories of EMC Emissions: radiated emissions, and conducted emissions. Radiated emissions relate to the H-field and E-field, while conducted emissions can be either continuous or discontinuous.

E-Field Radiated Emissions

Any electromagnetic interference that comes from frequencies generated by an electrical system or device is radiated emissions. Radiated emissions travel through the air either directly from the device or any of the device’s interconnected cables. EMC testing labs will measure radiated emissions by using an EMI receiver and measuring antenna, or a spectrum analyzer.

H-Field Radiated Emissions

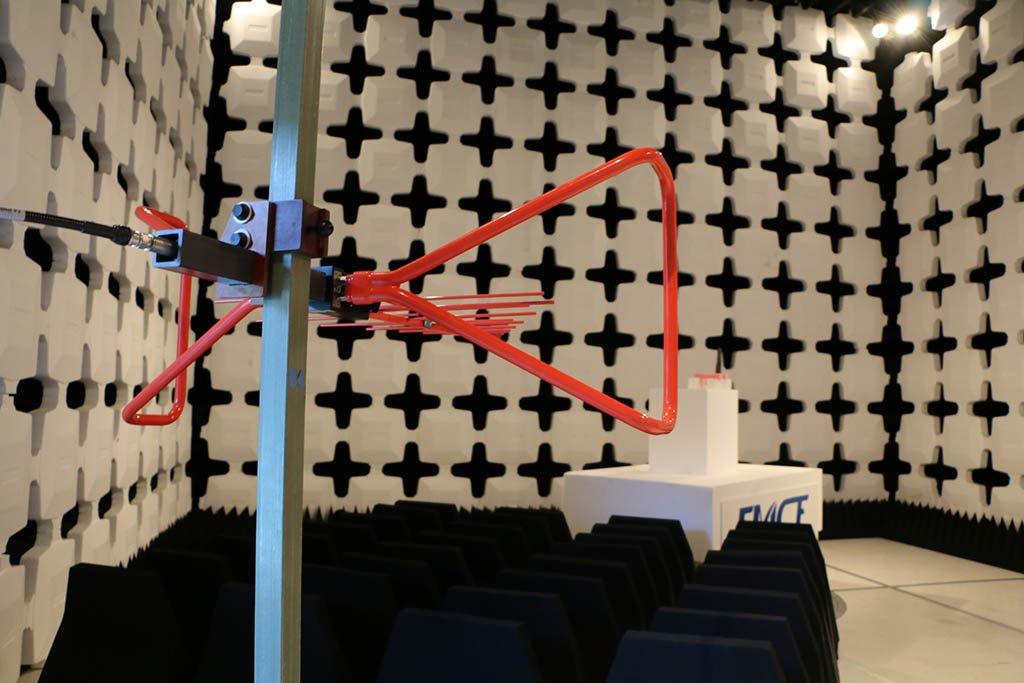

The H-field is the magnetic field, and this is measured using either an EMI receiver and a measuring antenna or a spectrum analyzer. The kinds of magnetic field antennas typically used in EMC testing are loop antennas. For EMC compliance testing, a particular antenna called the Van Veen Loop is used, which measures the emissions of the electronic device or system on three separate axes.

Conducted Emissions (Continuous and Discontinuous)

Both continuous and discontinuous conducted emissions are electromagnetic interferences (EMI) that come from frequencies generated inside the electronic gadget or system. These emissions are carried along with cables, such as power conductors or telecommunication ports. Continuous emissions are regularly emitted at a given frequency, while discontinuous emissions are not constant or predictable. For both types of conducted emissions, EMC testing labs will measure conducted emissions on an EMI receiver. An ISN – impedance stabilization network – which is located within the test chamber, transmits this information.

Immunity Testing for EMC

When performing EMC compliance testing for device immunity, testing can be either continuous or transient. This can depend on the type of electrical device or system being tested. Transient tests tend to be used for electrical that may exhibit sudden energy bursts, while continuous testing is used to simulate RF proximity.

Continuous Immunity Testing

There are several types of EMC compliance testing methods for continuous immunity.

- Radiated Immunity: The equipment and cables being tested are exposed to an electromagnetic field created by RF signal generators by a radiating antenna. This is a standard test for any product requiring EMC compliance testing.

- Power-Frequency Magnetic Field Immunity: The performance of the equipment being tested is evaluated by placing it inside a fluctuating magnetic field that has been generated by a magnetic coil oscillating at 50/60Hz. Usually only needed for magnetically susceptible devices.

- Conducted Immunity: An electromagnetic field is created and then connected to a product’s signal, power port, or data by an injection device. It usually applies to AC and DC ports, as well as any signal cables that are over 3m long.

Also Read: 15 Essential Elements of an EMC Compliance Testing Plan

Transient Immunity Testing

Transient immunity testing is another essential type of EMC testing. There are several tests used, which include testing for:

- Electrostatic Discharge: The enclosure of the device being tested is exposed to ESD pulses and coupling planes, at precise levels for the particular standard being tested.

- Surges: Surge testing applies to the mains port of the device being tested and typically applies to AC ports, occasionally DC ports, and in cases where signal cables over 30m run outside the building.

- Electrical Fast Transient and Bursts: Fast transients testing is an EMC testing procedure for AC power ports, DC ports, and signal cables over 3m long. Fast transients are high amplitude and repetition frequency pulses, generally triggered by high-speed switching events.

- Pulsed Magnetic Field: The product undergoing EMC compliance testing is put inside a magnetic loop, and is then exposed to a magnetic field pulse created by a transient generator.

- Voltage Variations and Dips: This kind of EMC testing can simulate any faults existing in the power network. Defects are usually caused by power outages or drastic changes in loads. This kind of test is only used for AC input ports.

Conclusion

EMC testing methods are essential in maintaining the quality and performance of electronic devices and systems. It also ensures that they meet compliance standards. This guide has outlined the main methods of testing for electromagnetic compatibility (EMC). These tests can be performed by EMC testing laboratories, using specialist equipment.