EMC Basics: What Is Radiated Emissions & Immunity Testing?

EMC (Electro-Magnetic Compatibility) tests regulate the radiated emissions of electronic devices. This test measures the functioning of equipment in electromagnetic environments. Under the EMC Directive, the device under testing should not introduce disturbances to the environment. EMC testing ensures the safety of an electronic device for consumer use.

In most markets, EMC certifications are mandatory. These certifications verify that a product meets regulations as established by the EMC Directive. These certifications also can improve the performance of a product. There are four EMC pre-compliance tests. Here, we’ll cover two radiated tests: immunity and emissions.

There are three main issue classes:

- Emission is the production of electromagnetic energy. Emissions occur when a source emits heat into the environment. These emissions can interfere with other electronic devices. As such, EMC studies monitor for unwanted emissions. They also propose countermeasures to minimize emissions.

- Susceptibility is the tendency of an electrical device to malfunction. This can be due to unwanted emissions or radio frequency interference. Immunity is the ability of machines to function while RFI is present.

- Coupling is the mechanism or equipment that emits interference to reach the victim.

Radiated Testing

Radiated tests monitor accidental electromagnetic energy released by electronic equipment. Radiated tests are the most common worldwide of EMC tests.

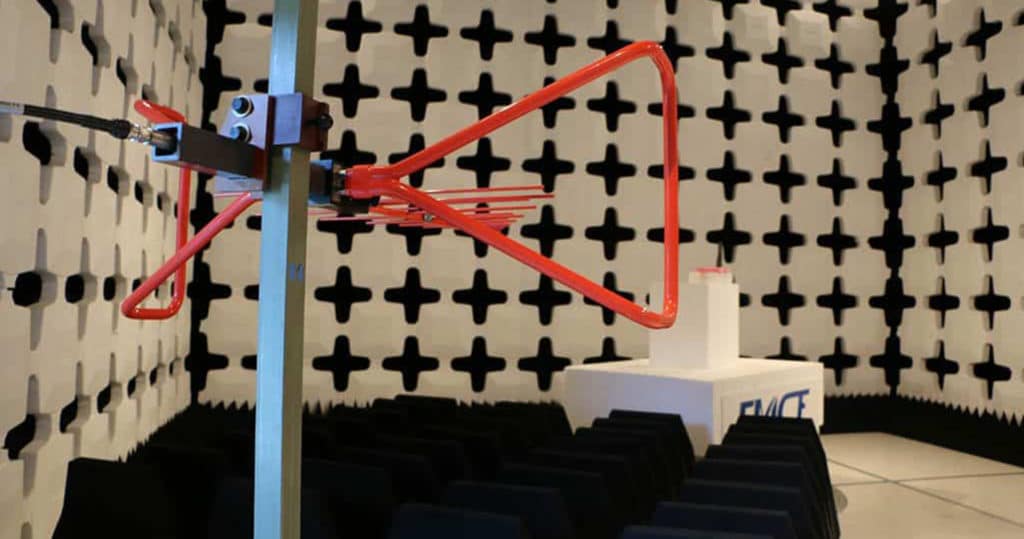

Electronic products must comply with the standards of emission limits. To meet these requirements, a manufacturer must send the products to a test house. The testing center will put the product into semi-anechoic chambers with antennas pointed toward it. The antennas capture phenomena were radiating from the device.

Before sending a device to a test house, you must conduct pre-compliance tests on your own. Doing so will save you money. It also will prevent delays in your production schedule that might otherwise result if the device doesn’t pass the testing phase.

Here’s a closer look at the two types of radiated tests:

Radiated Testing – Emissions

Radiated emissions testing isn’t as simple as conducted emissions testing. Radiated tests require through-the-air testing. This complicates the measurement of emissions. The added complexity stems from the ambient environment. This can interfere with the device under tests (DUTs).

The test distinguishes the signals coming from your device vs. the environment.

Radiated emissions testing measures the EM energy strength of your device’s emissions. Most, if not all, machines have some emissions. Testing ensures those emissions are compliant with the standards of your target market.

EMC compliance testing requires specialized test equipment: EMI test receivers and EMI analyzers. These devices incorporate detectors and bandwidths specified by international standards. EMI receivers utilize spectrum analyzers to measure DUT emission levels. The analyzers measure emissions across a full frequency band.

You also can measure these levels on a tunable narrower-band device. This device sweeps through the chosen frequency range. You can use EMI receivers and transducers for both radiated and conducted emissions.

Radiated Testing – Immunity

Radiated immunity tests measure the susceptibility of your device. Emissions from other devices in the surrounding area could affect your device. For example, if you manufacture phones, you need to know if the emissions from a nearby device could harm your product.

Immunity ensures that your device can withstand the emissions of surrounding gadgets. Otherwise, the interference can lead to a host of problems down the road.

Transient vs. Continuous EMC Phenomena

There are several types of EMC immunity tests. The most common of these are continuous and transient. You need to know which kinds of tests apply to your device before sending it in for EMC testing.

Continuous tests monitor for endless waves emitted by a device over time (minutes to hours). Permanent waves appear in modulation. These tests apply to gadgets that exhibit emissions at a specific frequency. The test is suitable for devices that stimulate RF proximity.

Transient tests monitor for evanescent waves, which appear in short bursts. Transient phenomena can come and go within microseconds. These tests apply to gadgets that exhibit a non-continuous rate of emission.

EMC Directive

The European Parliament and its member states developed EMCDirective 2014/30/EU. This Directive established harmonized standards for regulating electromagnetic emissions from devices. Although introduced by the EU, these regulations apply to markets in other countries as well. These include North America, Australia, Korea, China, and New Zealand. For these markets, a company must submit the EMC Declaration of Conformity to the notified bodies.

The Directive created conformity assessment procedures. These ensure that electronic devices do not create electromagnetic interference (EMI). EMI can disturb telecommunication and radio devices. It can affect other types of equipment as well. The Directive governs the immunity of these devices to prevent disturbance from radio emissions.

The EMC Directive regulates the EMC of electronic devices. Devices must follow EMC standards before becoming available on the market. The rules of the EMC directive include:

- Manufacturers must indicate their registered trade name or trademark on the device. They must list the address for contact information.

- Equipment must have a type, serial number, or batch, to allow for its identification. If the size of the apparatus doesn’t allow it, this information should be present on the packaging. It can also be on a document that comes with the device.

- All equipment must have instructions and safety information.

- Manufacturers who believe their product does not comply with standards need to take corrective action. If they aren’t taking corrective action, they need to recall the product. If the product poses a risk to consumers, they must inform national authorities.

EMC Lab Testing

For reliable electromagnetic compatibility EMC testing, you’ll want to work with an EMC test lab. EMC labs can simplify the compliance testing process. With the right resources, they also can make testing more cost-efficient.

Look for an EMC testing lab with global EMC accreditations. Make sure the EMC test lab you choose has various centers, certification types, and EMC testing services. Other services these labs can provide include testing for safety, energy efficiency, environmental impact, performance, and more.

The lab should have top of the line testing equipment. They also should provide technical documentation outlining the completed tests.

Final Thoughts

EMC testing verifies electronic devices are ready for public use. Strict usage standards ensure the safety of consumers and prevent EMI with other devices. With EMC testing, you can release your product to your target market with confidence.

We hope this piece gave you a clearer understanding of all the facets of EMC testing. Check out some of our other posts to learn more about EMC and the pre-compliance tests before putting your product on the market.